The most comprehensive Cobot Fabrication portfolio on the market.

We offer a variety of system configurations to meet your exact application and production needs, all on a robust, commonized software platform.

You’re always protected with our unprecedented 30-day return policy, industry-leading 2 year warranty, and best-in-class support & software.

View our most common configurations, and then get in touch with our expert applications team to determine the right tool for the job!

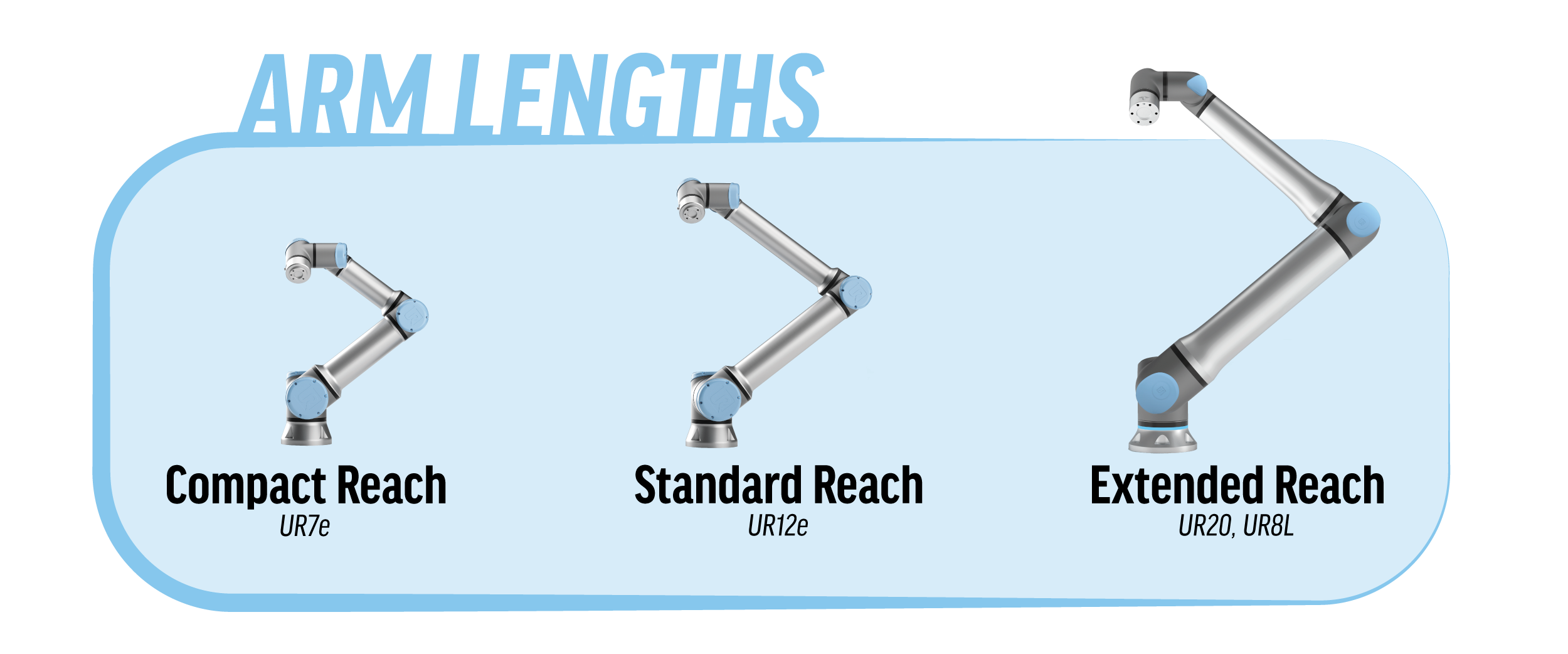

From compact reach for maximum portability, to extended reach for long parts, Vectis offers a range of industry-leading Universal Robots arms to adapt to your applications — a proven 6th-gen platform with over 100,000 arms deployed worldwide.

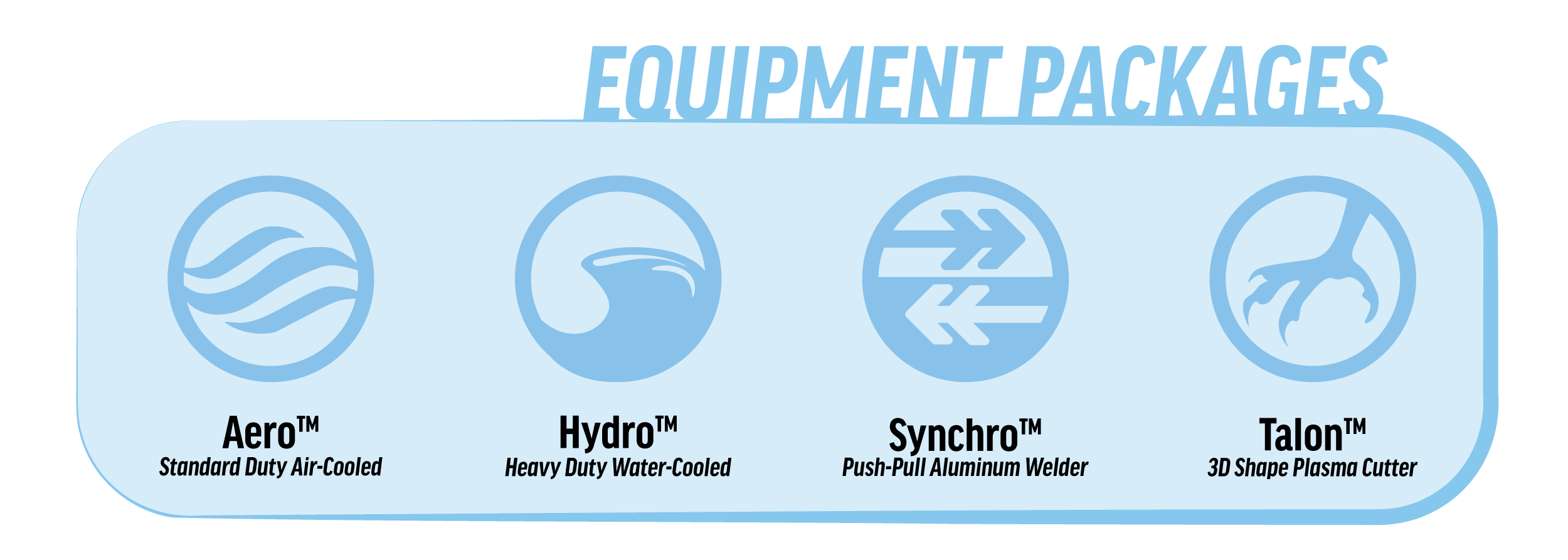

Vectis’ Aero, Hydro, Synchro, and Talon equipment packages offer powerful options for a variety of application needs, all from industry-leading brands.

Vectis remains your unbiased partner, enabling your shop to choose the right package for the job.

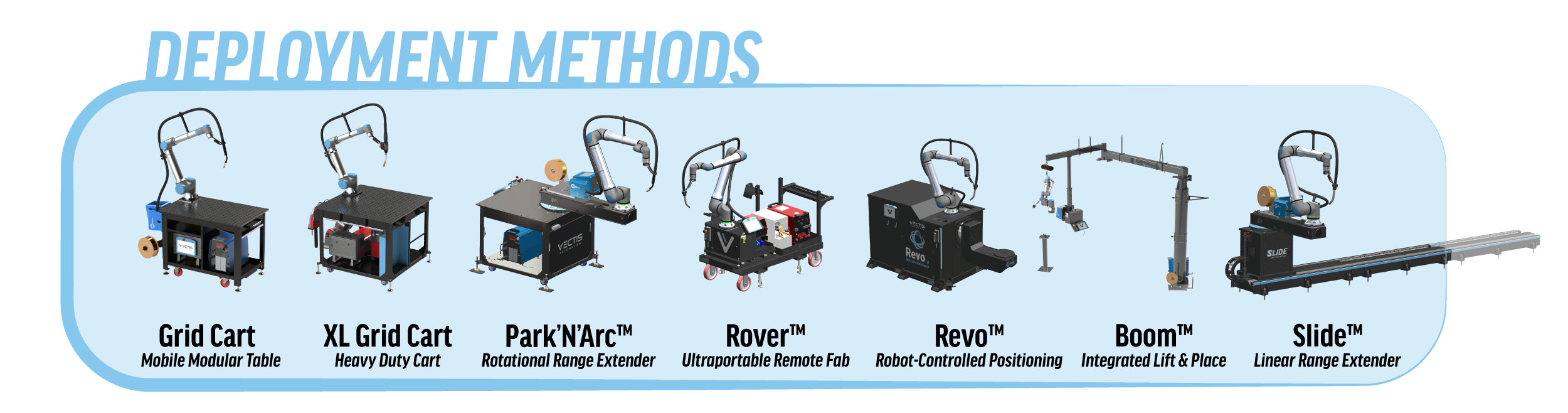

The industry knowledge from centuries of combined experience, thousands of shop floor visits, and 800+ successful deployments has inspired the range of Vectis deployments; standardized products suited to the real-life production needs of fabricators.

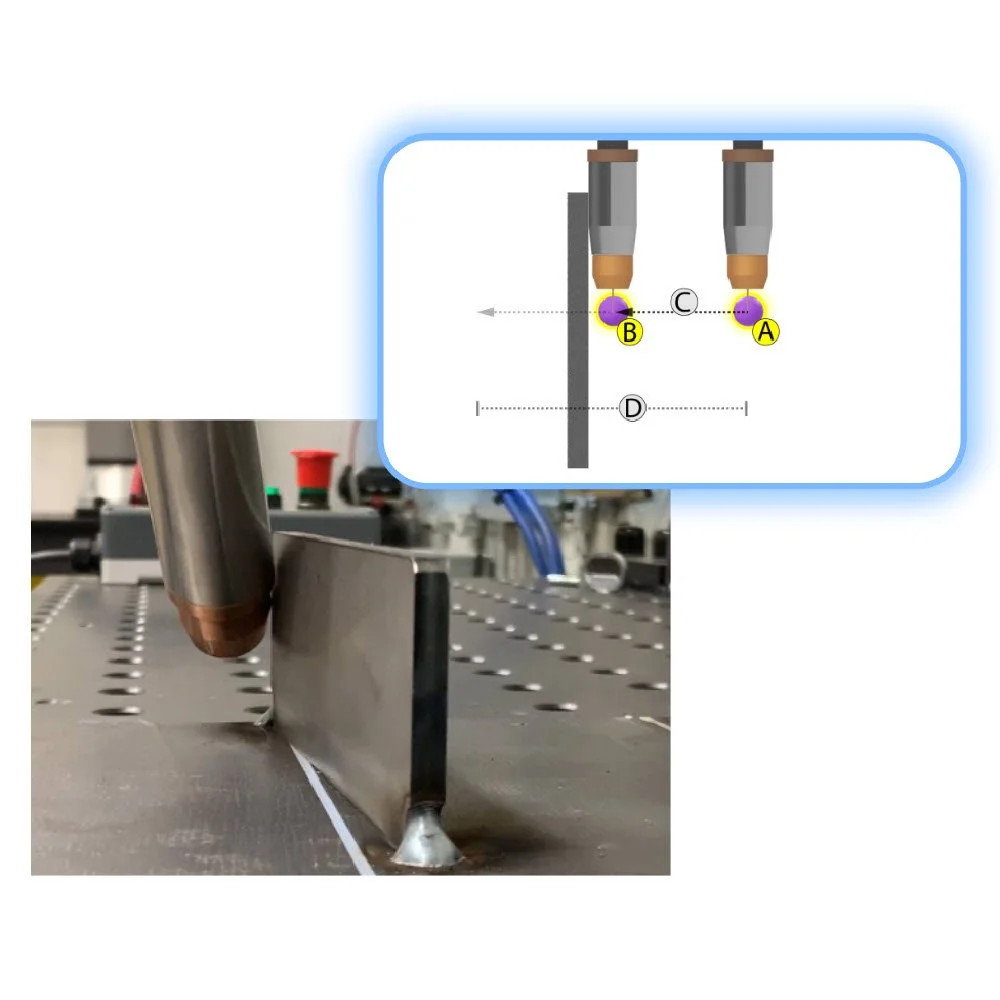

Common Part-to-Cobot Deployments: Compact, Mobile Flexibility

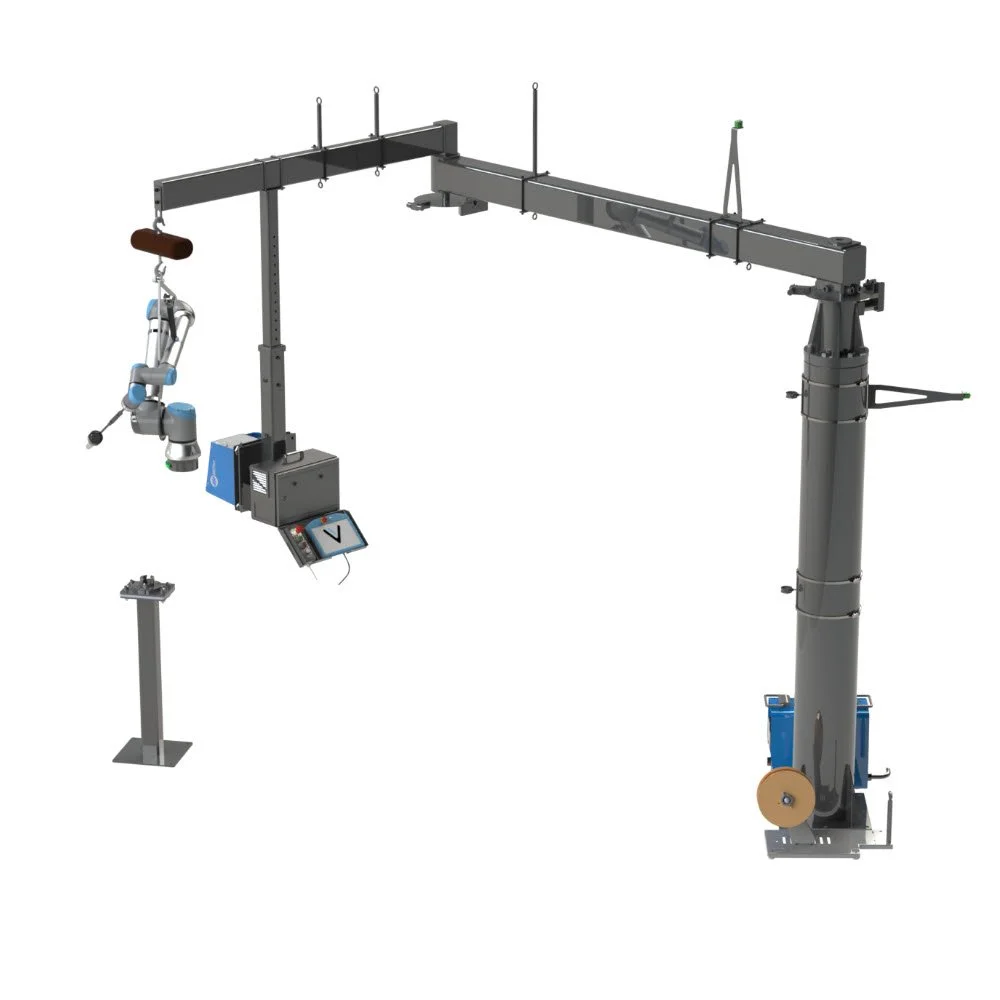

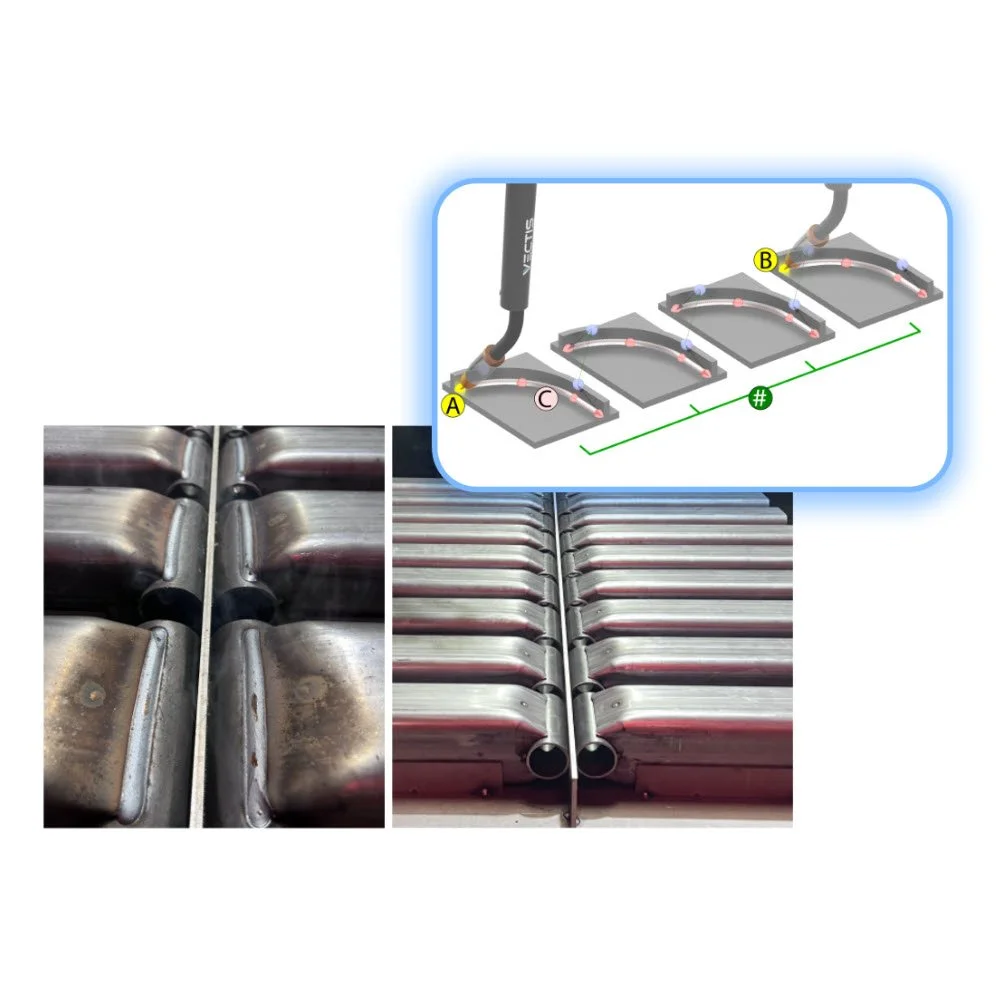

Common Cobot-to-Part Deployments: Boundless, Remote Cobot Deployment

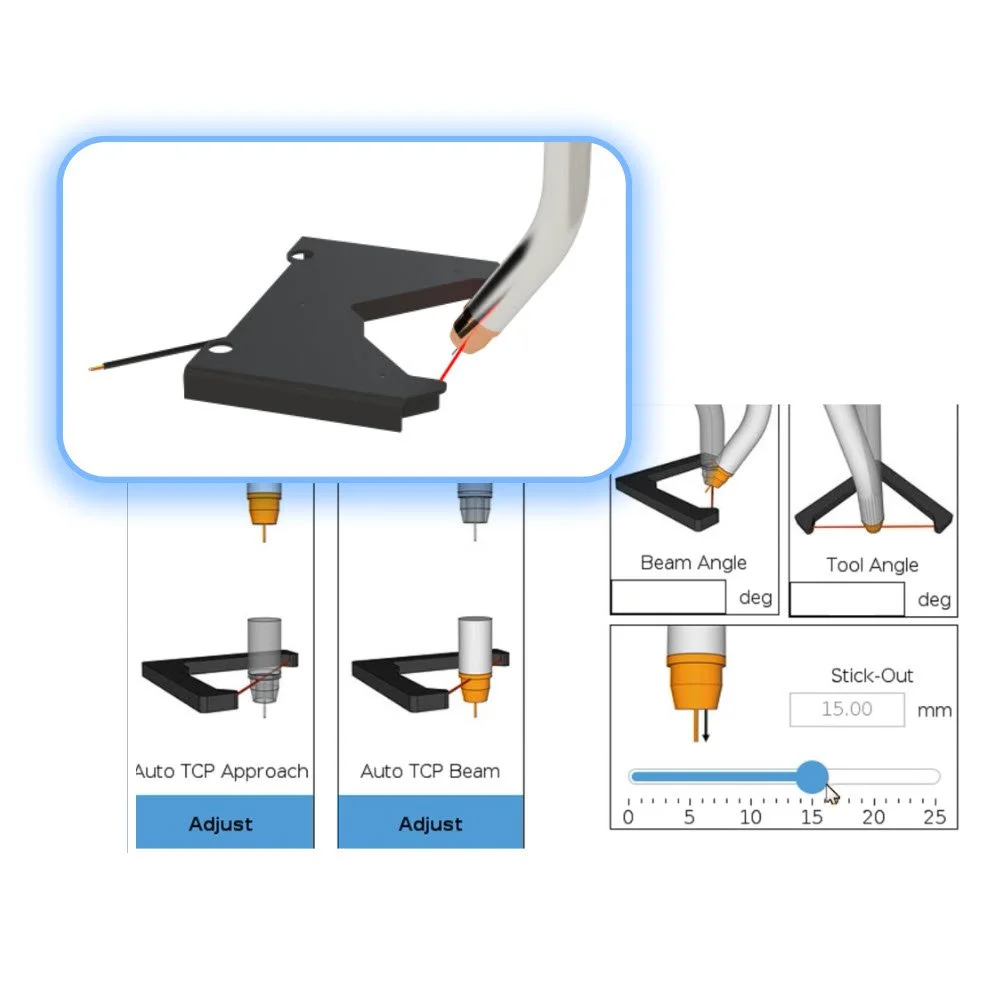

Key Features and Vectis Advantages